Customized Ultrasonic double layer glass reactor

Product Description

Introduction:

Different cold and hot circulating fluid (hot water / hot oil / freezing liquid) can be put into the layer of double Glass reactor. In the sealed glass container, the reactants are stirred and distilled at normal pressure or negative pressure and can be used for various biochemical synthesis reactions under constant temperature conditions, and can also be reflux or distilled at different temperatures.The reaction kettle covers different openings to realize the different effects of feeding, measuring temperature, recovering distillates and so on.

The full transparent reaction process is an ideal test equipment for modern fine chemicals, new biochemicals research and development, pharmaceutical intermediates, precious metals purification, new graphene energy materials and aerospace materials, and it can also be used for mixing, distillation, thickening, separation, extraction or crystallization.. Qi Yu company keeps pace with the times, can provide the reaction kettle system from simple kettle to complex process. The product can be used with circulating water multipurpose Vacuum pump, high and low temperature circulation device, one-stop matching, for your free expansion of the ideal choice of reaction synthesis.

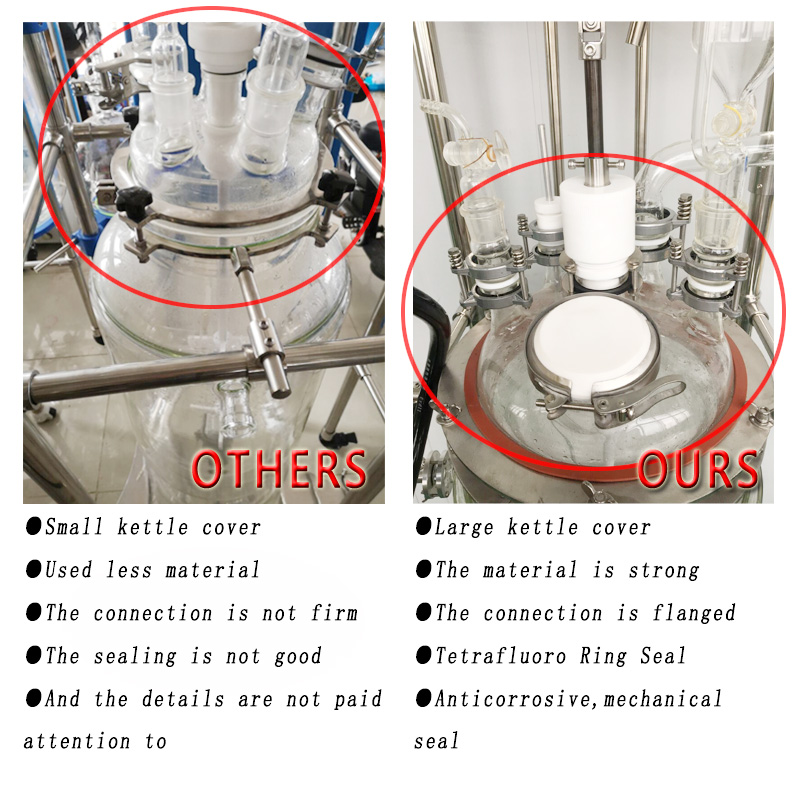

All glass products in the glass reactor are made of high borosilicate glass and expanded coefficient 3.3. Its smooth and uniform surface ensures no material bond, easy to clean, better perspective and easy to observe the process; it is made of SiO2, B2O3, NaO, Al2O3; it has anti chemical corrosion resistance, high temperature resistance to a variety of acid, salt solution, organic intermediates, disable hydrofluoric acid, high concentration phosphoric acid, and alkaline solution. The temperature should not be higher than 50 degrees centigrade; the temperature range of the glass parts is from -80℃to +200℃; the heat resistance is less than 120 ℃, and the operating pressure of the glass parts (the pressure range is different for different temperatures and DN diameters), from -0.1Mpa to 0.4Mpa.

Here we provide various specifications of the reactor, the volume from 250 mL to 200L single and double decker.You can also customize different specifications of the reaction kettle according to your needs.

Application:

1. Fine Chemicals

2. Biochemical New Drug Development

3. Pharmaceutical Intermediates

4. Purification of Noble Metals

5. Graphene New Energy Materials and Aerospace Materials

| Model | QYCS-30 |

| Glass material | Borosilicate glass GG17, expansion coefficient 3.3 |

| Outer gallbladder frame and flange material | 304 stainless steel |

| Reaction bottle volume of inner tank | 30L |

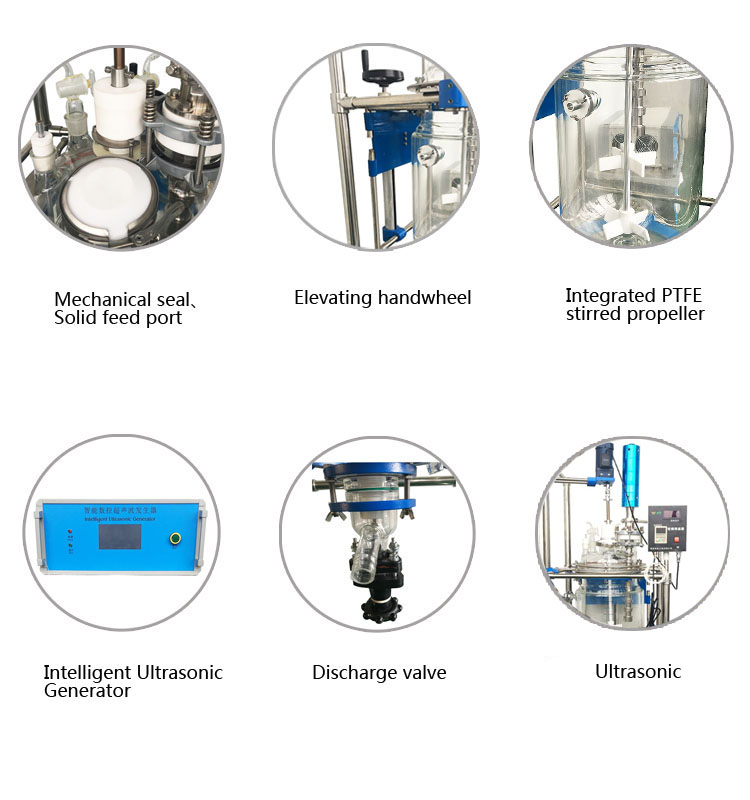

| The number of the bottleneck | The material of the cover is PTFE,the diameter 340mm and it has 6 openings.(Stirring DN40, Liquid feeding port 29#*2, Thermometer 29#, Solid feeding port DN80, Ultrasonic discharge DN40) |

| Discharge port from the ground | 400 mm(Height can be adjusted according to ventilation cabinet height and operating habits.) |

| Reaction temperature of the reactor | `-90~250 ℃(In the short term, it can reach 300 ℃) |

| RPM/Minute | 0-400 |

| Stirring power | 120W /1:3 |

| Voltage(V) | 220V/50HZ |

| Dimensions | Height can be adjusted according to ventilation cabinet height and operating habits. |

| Speed regulation mode | Frequency control |

| Speed display mode | LCD digital display |

| Sealing method | Mixing mechanical seal |

| Up-down mode of kettle | Mechanical lifting of manual wheel |

| Digital display temperature measurement | Teflon PT100 sensor No fracture Accuracy±0.5℃ |

| Discharge method | Top type without dead ends,Oblique discharge glass discharge valve |

| Agitation method | Floppy soft connection |

| Muddler | Four leaf push type 316L Outsourced tetrafluoro Diameter 17mm |

| Ultrasonic optional frequency range | 15KHz~60 KHz |

| Unit nominal power | 2000W |

| Vibrating rod tool head (probe) material | Imported high quality titanium alloy |

| Configuration of ultrasonic driving power supply | Intelligent numerical control power supply V7.0 |

| Working frequency | 20±1kHz |

| Power input parameter | 220V/50HZ |

| Drive power supply | Numerical control power supply:Frequency detection, Frequency automatic tracking, Overflow over pressure protection |

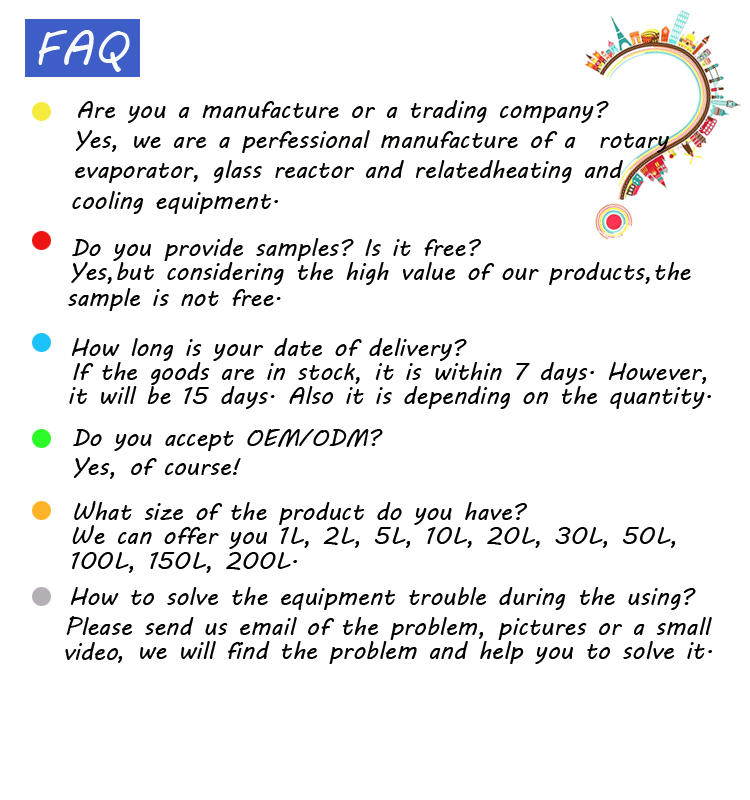

Qiyu Industrial (Shanghai) Co., Ltd. is located in the Jiading District Industrial Park of Shanghai city. We have considerable experience in R&D, and have obtained the national patent. We mainly produce glass reactor, Rotary evaporator, short-path Molecular distillation, Temperature control system, vacuum equipment and other types of equipment.

The company has strong technical force, complete production equipment, continuous absorption of advanced technology at home and abroad, and active development of new products.

We will continue to pursue the dedication of "honesty and innovation", and provide customers with perfect pre-sale, sale and after-sales service. Internationalization and standardization will transform innovation into productivity and let customers to use synchronized international products

Pre-sale:

1. Provide free technical advice.

2. Design proposals can be issued according to customer requirements.

3 . The seller can provide detailed equipment parameters and configuration list.

After sale:

1. The warranty period of the company's products is 12 months from the date of acceptance of the equipment (excluding glass fittings and consumables);

2. If there are quality problems in the parts during the warranty period,

the seller can provide free replacement of malfunction components; if the damage is due to human factors, when the parts need to be replaced, the seller will provide the accessories and charge the maintenance cost according to the price.

3.For on-site installation and commissioning, additional charges will apply.

Product Categories : Glass reactor > Customized reactor